MGDM offers excellence in precision engineering with sixty years of experience in the aerospace, defense and automotive industries. You will find advanced production capabilities maintaining tight tolerances using cutting-edge laser cutting, welding and machining technologies. They ISO certified quality management system guarantees constant compliance with international standards. Year-round repair services minimize downtime, while their significant investments in research and development (30% of assets) promote innovation continues. Discover how their mastery of specialized materials can transform your most demanding technical challenges.

Main results

- MGDM combines six decades of precision mechanical expertise with advanced manufacturing technologies for the aerospace, defense and automotive industries.

- The comprehensive infrastructure includes precision sheet metal processing, laser cutting and sophisticated welding systems, supported by CAD/CAM design capabilities.

- Strategic industry partnerships highlight MGDM’s reliability in delivering custom components to tight precision tolerances.

- Year-round repair services and preventative maintenance programs minimize operational downtime for customers in the most demanding industries.

- Significant investments in research and development (30% of resources) stimulate innovation while maintaining quality thanks to ISO 9001 and EN ISO 15085 CL2 certifications.

60 years of experience in precision mechanics: MGDM’s heritage of excellence

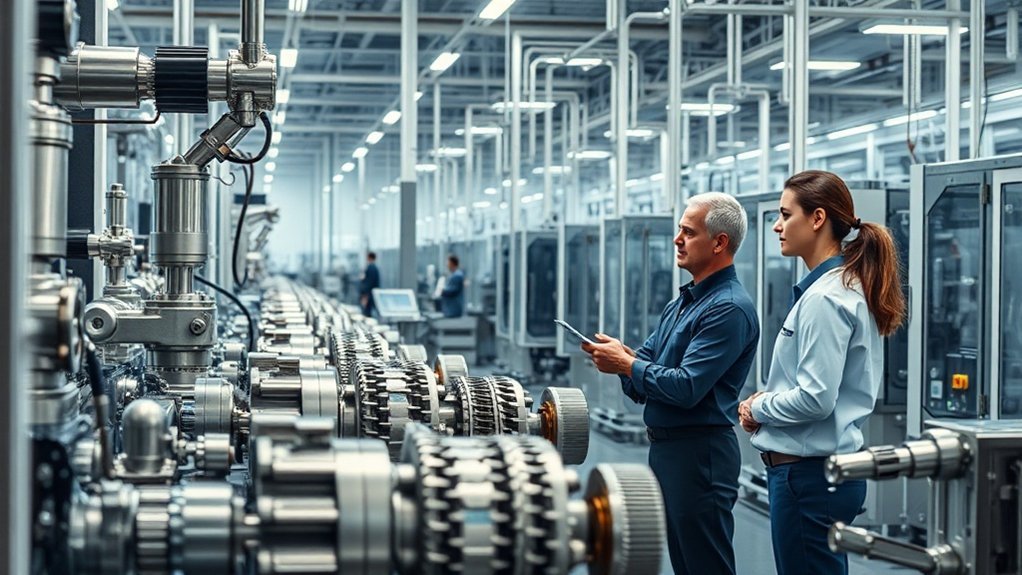

The commitment defines MGDM’s sixty-year journey precision mechanicsestablishing the company as an industry pillar since its inception. This legendary impact extends to the aerospace, defense and automotive industries, where competent technique of MGDM has consistently provided superior mechanical solutions.

The development of the company’s skills follows a methodical path, evolving from traditional grinding to advanced production techniques. With 45 trained professionals using state-of-the-art equipment, MGDM maintains precision standards that exceed industry expectations.

Their certifications ISO9001 and EN ISO 15085 CL2 validate this technical excellence.

You will find theengagement of MGDM towards innovation particularly evident in their investments in research and development. This forward-thinking approach ensures that their manufacturing capabilities continually adapt to your evolving needs, strengthening their position as a trusted partner manufacturing of custom precision components. Furthermore, the use of innovations in stainless steel plays a crucial role in improving the durability and performance of their mechanical solutions.

Cutting-edge manufacturing capabilities for complex engineering challenges

THE’advanced production infrastructures by MGDM represents the culmination of technological integration between different precision disciplines. Their laboratory houses cutting-edge technologies specially designed for precision sheet metal processingincluding equipment for laser cutting sophisticated and advanced welding systems that guarantee exceptional precision.

Faced with complex engineering requirements, processing capacity MGDM’s comprehensive databases become invaluable. Their specialized turning, milling and drilling techniques transform raw materials into precision components that meet the most demanding standards aerospace and automotive industries.

THE integrated design office of the company further strengthens its mastery of precision manufacturing. Using advanced CAD software and 3D prototyping, MGDM develops tailor-made solutions suited to your specific challenges.

This technological ecosystem, supported by ISO 9001 certification and rigorous quality control, ensure that each component meets the highest performance criteria. Furthermore, the use of stainless steel in their processes offers superior durability and corrosion resistance, essential for demanding applications.

Strategic partnerships in the aerospace, defense and automotive sectors

While maintaining strict precision tolerancesMGDM has forged strategic partnerships with leading organizations in the aerospace, defense and automotive industries over its sixty-year history.

These collaborations highlight the company’s reliability in delivery customized mechanical components to answer industry-specific requirements.

You will find MGDM’s expertise reflected in numerous collaborative projects that respond to emerging industry trends.

Their approach combines conventional machining with digital production methods to meet the evolving needs of high-demand industries.

The company’s services extend beyond manufacturing to include urgent repairs and preventative maintenance, ensuring operational support throughout the year.

MGDM’s adaptability has allowed it to remain relevant as technical specifications advance, demonstrating why major players continue to trust their precision engineering capabilities for critical applications where quality cannot be compromised. Furthermore, they respect the materials and standards which are essential for a robust industrial piping system, thus improving their operational excellence.

Year-Round Repair Services: Ensure continuous operations for customers

Since machine failures can occur unexpectedly, continuous access to repair services it becomes essential to maintain it operational efficiency. MGDM responds to this need by providing repair services year-round, including during the summer months and holiday seasons, when support availability typically declines.

When your mechanical parts are broken, worn or damaged, the urgent repairs of MGDM minimize operational downtime, a critical factor for industrial productivity.

Their ongoing support goes beyond reactive solutions to include preventive maintenance programs which prolong the life of equipment and reduce the frequency of failures.

Technical consultations complement these services, allowing you to make data-driven decisions about your mechanical components.

Innovation through advanced technologies and specialized materials

On the front lineprecision engineering MGDM’s complete technology ecosystem is located, where cutting-edge machines interact with a specialized hardware expertise to deliver exceptional production results.

You will benefit from their mastery of various materials: steel, stainless steel, aluminum, bronze, brass and plastic, allowing for optimal performance in your specific applications.

They technological advances go beyond materials to include sophisticated CAD software and 3D prototyping capabilities. These tools allow the MGDM design office to create tailor-made solutions face your unique challenges.

The company’s hardware innovations come from a substantial investments in research and development—30% of resources—continuous development of new manufacturing processes and products.

MGDM’s commitment to excellence does not compromise environmental responsibility; they integrated ecological practices and recyclable materials in their production, ensuring sustainable production together with precision.

Certified quality management: compliance with the highest industry standards

THE’technological excellence of MGDM finds its formal validation through a framework of quality management complete, based on prestigious international certifications. Operate according to standards ISO9001EN ISO 15085 CL2 and EN ISO 3834-2, the company demonstrates a constant commitment towardsprocess optimization in precision mechanics.

Son quality assurance system incorporates meticulous traceability mechanisms for internal and supplier-supplied components, ensuring complete traceability throughout the entire production process. You can see their approach especially evident in their exhaustive machining, inspection and manufacturing procedures.

The implementation ofinternal and product audits Regular monitoring further strengthens MGDM’s quality infrastructure, verifying that all processes consistently meet international standards.

This methodological pursuit of excellence translates directly into a greater reliability produced parts, positioning MGDM as a trusted partner for industries where precision is not only desirable, but essential.

latest posts published

Law enforcement agencies are invited to assess the circumstances of road construction in the Trakai district

New automotive technologies: when to take a break from driving?

Winter tyres: from retreaded to studded. Which is better?

Car security systems – enginegeek.online

Autonomous cars will change the way people think about traffic jams

Altas Auto introduced the first electric buses

How and with what to disinfect the car to avoid becoming infected by the coronavirus?

Mazda CX-5 has learned to recognize pedestrians at night

When is it necessary to change the oil? – enginegeek.online