Stainless steel combines iron, carbon and chromium (minimum 10.5%) to create corrosion resistant alloys. You’ll find five main classifications: austenitic, ferritic, martensitic, duplex, and precipitation hardening, each with distinct properties. His exceptional strength/weight ratioIts temperature resistance (-196°C to +925°C) and workability make it an ideal material for food processing, medical instruments, construction and automotive applications. The selection criteria must favor the environment-specific performance : 316 pour chemical exposure304 for general applications. The following analysis explores the technical specifics of each grade in detail.

Main results

- Stainless steel contains a minimum of 10.5% chromium which forms a self-healing oxide layer that provides exceptional corrosion resistance.

- Major classifications include austenitic, ferritic, martensitic, duplex, and precipitation hardening, each with distinct properties and applications.

- Maintains its mechanical integrity at extreme temperatures ranging from -196°C to +925°C, suitable for cryogenic and high temperature applications.

- Grade 316 excels in chlorinated environments while 304 offers cost-effective corrosion resistance for general applications.

- Advanced manufacturing processes include passivation, electropolishing and additive manufacturing for specialized industrial requirements.

Understand the metallurgical composition of stainless steel

Three essential components define the fundamental structure of thestainless steel : iron as base metal, carbon in concentrations up to 2.1% and chromium with a minimum threshold of 10.5%.

You will find that Chrome creates a file chromium oxide layer car repair, offer corrosion resistance which distinguishes stainless steel from standard carbon steel.

Microstructural analysis reveals how alloying elements additional properties transform the properties of stainless steel.

Nickel improves the ductilitywhile molybdenum increases resistance to chlorinated environments.

Titanium improves performance at high temperatures through stabilization processes.

The five main classifications – austenitic, ferritic, martensitic, duplex and precipitation-hardened – each show distinct crystalline structures and mechanical behavior.

These variations give average Brinell hardness measurements around 250, demonstrating theexceptional strength/weight ratio of stainless steel compared to other metallic materials. Furthermore, the use of stainless steel ensures the longevity and reliability of components subjected to extreme environments.

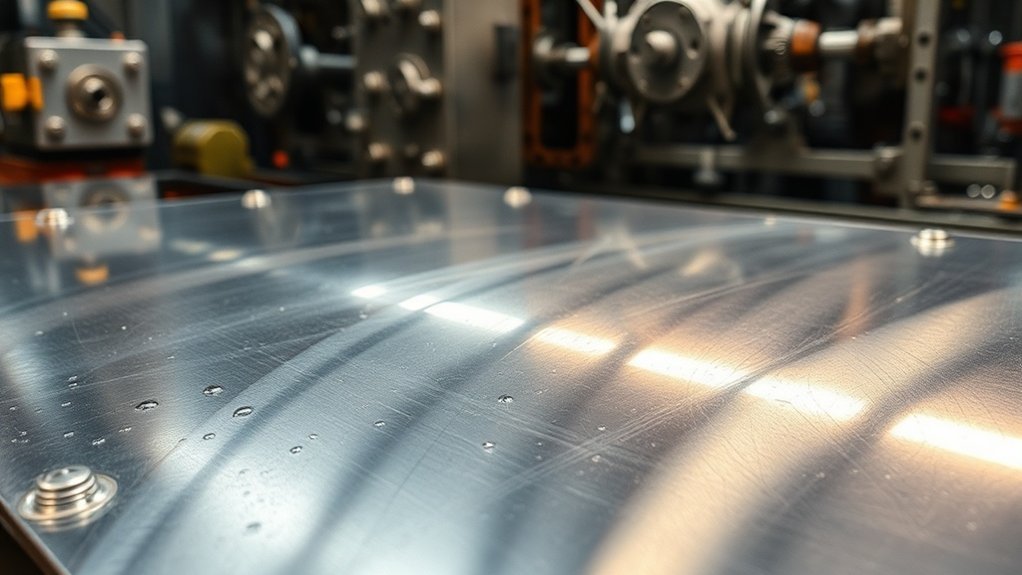

Essential technical properties and performance characteristics

Stainless steel has exceptional technical properties that essentially distinguish it from conventional building materials.

You will find that it is remarkable corrosion resistance derives mainly from chromium contentwhich forms a protective and self-repairing oxide layer that prevents oxidation and rust formation.

THE tensile strength The impressive material provides superior mechanical reliability in various applications requiring durability. Different grades offer different performance profiles: 316L excels in chlorinated environments while 304 provides versatile protection.

What is especially valuable is the ability to do this stainless steel to maintain it mechanical integrity Through extreme temperatures (-196°C to +925°C), making it suitable for cryogenic and high-temperature applications.

Its excellent workability allows it to be shaped into complex geometries without compromising structural integrity.

These properties combine to provide exceptional performance food processing equipmentmedical devices, architectural elements and critical industrial components where reliability cannot be compromised. Furthermore, 316L stainless steel corrosion resistance making it the ideal choice for harsh industrial environments.

Main grades of stainless steel and their distinctive characteristics

The stainless steel classification includes five broad categories, each with distinct metallurgical structures and different performance profiles.

Austenitic properties include high chromium-nickel content (16-25% Cr, 8-20% Ni), non-magnetic behavior and corrosion resistance superior, making them ideal for kitchen equipment and chemical processing. Furthermore, the versatility of stainless steel It allows it to be used in a variety of industries beyond those traditionally associated with its use.

Ferritic applications take advantage of their magnetic characteristics and moderate corrosion resistance in automotive components and household appliances, containing 10.5-22% chromium without a significant amount of nickel.

Supply of martensitic grades exceptional hardness thanks to a heat treatmentcontaining 12-16% chromium and a higher carbon content, ideal for cutlery and utensils.

Duplex steels combine austenitic and ferritic characteristics, providing greater strength and resistance to stress corrosion cracking for marine environments.

Precipitation hardening varieties achieve remarkable strength-to-weight ratios through specialized heat treatments, meeting the needs of aerospace and precision engineering where mechanical properties are critical.

Main industrial applications and selection criteria

When you select thestainless steel suitable for specific applications, it is necessary to consider both the environmental conditions and the performance requirements that influence the choice of materials in the various sectors.

In thefood industryGrades 304L and 316 dominate equipment manufacturing due to their excellence corrosion resistance which deals with acidic ingredients and their healthful properties for storage tanks and utensils.

Medical instruments benefit from the durability and biocompatibility of stainless steel, ensuring that surgical instruments maintain their integrity during sterilization cycles.

For the construction applicationstake into account the requirements of mechanical force for the structural elements, while automotive components require qualities that balance weight considerations with high temperature stability for exhaust systems.

Yours selection criteria should prioritize environment-specific performance: choose 316 for severe chemical exposures and 304 for general applications where cost-effectiveness is critical but corrosion resistance remains essential.

Advanced production processes and surface treatments

Although the traditional production methods remain valid for many applications, modern stainless steel production has evolved significantly advanced production processes which significantly improve the performance and versatility of the materials.

You will find that hot and cold working techniques create complex structures while optimizing the mechanical properties.

Passivation applies a protective layer of chromium oxide that prevents further oxidation, thus strengthening the corrosion resistance. For medical and food applications, the electrochemical polishing produces ultra-smooth surfaces that minimize bacterial adhesion.

Additive manufacturing represents a revolutionary approach, allowing complex stainless steel components to be created with less waste and shorter production cycles.

When specific performance characteristics are required, heat treatments such as annealing and tempering can be used to achieve precise levels of hardness and strength. These processes allow you to tailor the properties of stainless steel to your precise industrial needs.

latest posts published

Law enforcement agencies are invited to assess the circumstances of road construction in the Trakai district

New automotive technologies: when to take a break from driving?

Winter tyres: from retreaded to studded. Which is better?

Car security systems – enginegeek.online

Autonomous cars will change the way people think about traffic jams

Altas Auto introduced the first electric buses

How and with what to disinfect the car to avoid becoming infected by the coronavirus?

Mazda CX-5 has learned to recognize pedestrians at night

When is it necessary to change the oil? – enginegeek.online