At the Transport and Innovation Forum held in Vilnius, one of the most important topics was the most effective measures to achieve zero pollution, when technology experts, business and public sector representatives discussed the prospects of the logistics sector. Alexander Vlaskamp, Executive Vice President, Head of Sales and Marketing at Scania, drew attention to the crucial role of manufacturers in the transition to sustainable heavy transport.

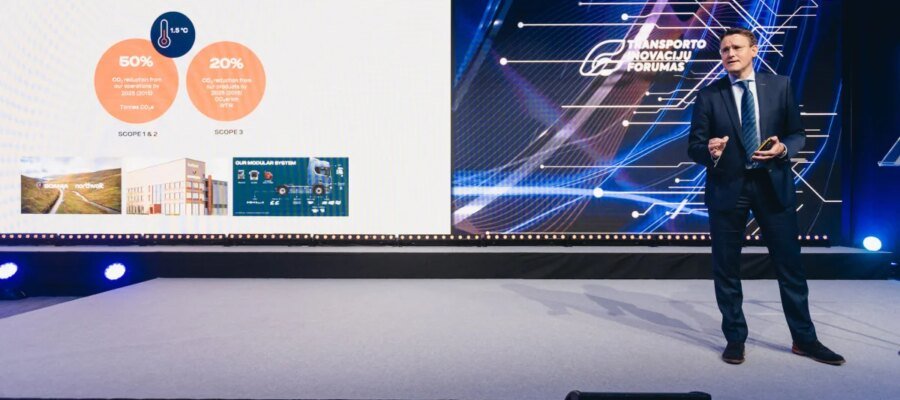

Scania is the first company in its sector to choose Science Based Targets as the main benchmark for gradually reducing carbon dioxide emissions. The goal is to reduce the CO2 footprint in the company’s operational processes by 50% by 2025 and in customer activities by 20%.

new challenges that will have to be overcome when switching

On the basis of this, it was decided in which areas to allocate the greatest investments, so that by 2025 the total CO2 emission of all vehicles produced by the company should be equal to 20%. smaller.

“This is more than the European Commission asked manufacturers in the same period, but if we want to be a company that promotes important changes, we must show everyone the results we have achieved”, underlined the vice-president of Scania.

It predicts rapid changes

According to A. Vlaskamp, the technological barrier has long disappeared. The Scania series produces electric and plug-in hybrid general cargo trucks. To ensure the supply of components, a new battery factory is currently under construction in Siodertèlje, Sweden.

Scania’s transition to electric traction is best illustrated by the strategic decisions of recent years. In the 1920s the manufacturer also invested in the more environmentally friendly battery factory in Šelèfteo, another Swedish city, being built by the company Northvolt, which supplies energy from renewable sources. This plant will supply lithium-ion cells for Scania truck batteries.

A. Vlaskamp expects rapid growth in sales of electric heavy-duty vehicles in the near future. It is expected that by 2025, 10% of all Scania trucks and buses sold in Europe will be electric, and this percentage is expected to increase to 50% in 2030. The company’s main goal is to produce only zero-emission vehicles by 2040.

The vice-president of Scania also underlined that, to achieve the objectives specified in the Paris Agreement on the reduction of climate change, it is necessary to promote a more rapid renewal of the technical park and significantly increase the use of biofuels and natural gas obtained from renewable sources.

In July the European Commission announced an extremely ambitious plan, according to which by 2030 greenhouse gas emissions compared to 1990 levels should be reduced by at least 55%.

Entrepreneurs need encouragement

A. Vlaskamp noted that in the future electricity stored in batteries will become the main source of energy for various types of vehicles. According to a Scania executive, the shift from diesel to electric heavy-duty vehicles would be encouraged by the company’s customers with the right infrastructure and tax incentives.

“During the transition period, the use of biofuels and natural gas will be extremely important. All solutions that lead to lower CO2 emissions compared to heavy diesel transport should be encouraged,” commented the company’s vice president.

A. Vlaskamp emphasized that customers will only choose alternative transport solutions if they see that they can be profitable. The producers’ task is to encourage the first entrepreneurs who decide to do so, but state incentives are important. A good example, according to the vice president of Scania, is even 80% in Germany. subsidies targeted at the value of an electric truck.

The Norwegian Postal Service is currently testing local electric Scania trucks on a 1,600 km long route between Oslo and Tromsø. The batteries installed in the heavyweights have a capacity of 300 kWh and a range of 250 km, so this is a serious test for a technology that is still relatively new.

As the technology improves, from 2023 Scania plans to produce extra heavy loads capable of carrying electric trucks. For a total weight of 40 tons, such a tractor could be operated continuously for at least four and a half hours, and for 60 tons – three hours.

“We are almost ready, but the infrastructure also needs to be adapted. A light electric car with electric drive is usually charged once a day. Tractor batteries will be charged twice and may require up to 1,000 kWh of energy,” explained A. Vlaskamp about the challenges ahead.

Infrastructure needs to be expanded

For the transport sector, efficient and versatile heavy vehicles are needed, but, as A. Vlaskampas noted, infrastructure capable of supplying them with energy is no less necessary. Doubtful entrepreneurs could be encouraged to switch to electric technologies thanks to the developed electricity grid, adapted to higher loads and the possibility of obtaining electricity from renewable sources. Another important issue is the significantly higher energy demand.

“In a medium-sized logistics center where goods are redistributed, between 500 and 800 trucks pass through each day. We keep in mind that these 500 arriving trucks will need to be recharged and each of their batteries will need 800 kWh. It is easy to calculate that a total of 40 megawatts of energy will be consumed, as much as in a medium-sized city. Therefore, it is necessary to ensure that the electricity networks are ready,” the companies explained. vice president

A. Vlaskamp emphasized that it is important to give transporters the opportunity to work as they are used to until now. This requires not only a sufficient energy supply to the logistics centers, but also charging stations between them, so that drivers can, if necessary, top up their energy reserves.

“Fundamental changes will happen when simple but not too expensive ways of charging electric vehicle batteries become available. Logistics companies need to be confident that after the transition they will be able to work as before,” said Scania’s head of sales and marketing.

The abandonment of fossil fuels, according to A. Vlaskamp, would be helped by higher taxes on pollution and benefits for those who avoid it. According to the specialist, close collaboration between different sectors and more active involvement of legislators are needed to implement international sustainable transport projects and stop climate change.

“The most effective way to drive change is to work together with partners. We are already signing strategic contracts with suppliers of electricity produced from renewable sources, companies that produce batteries with a low CO2 impact and even smelt steel without fossil fuels,” said the Scania vice-president.

A. Vlaskamp also cited a good example of close collaboration. The Traton Group, which includes truck manufacturers Scania and MAN, together with the Volvo Group and Daimler Truck, plans to invest more than 1 billion euros over the next five years. euro and install at least 1,700 public charging stations near the most important European roads.

latest posts published

Law enforcement agencies are invited to assess the circumstances of road construction in the Trakai district

New automotive technologies: when to take a break from driving?

Winter tyres: from retreaded to studded. Which is better?

Car security systems – enginegeek.online

Autonomous cars will change the way people think about traffic jams

Altas Auto introduced the first electric buses

How and with what to disinfect the car to avoid becoming infected by the coronavirus?

Mazda CX-5 has learned to recognize pedestrians at night

When is it necessary to change the oil? – enginegeek.online